Contractors should update inventory plans to get ready for equipment changes

Big changes are coming to the HVAC industry, as of January 1, 2023, the Department of Energy’s (DOE’s) minimum energy efficiency requirements go into effect for all newly manufactured residential and commercial air conditioners and heat pumps. On the commercial side, this will mark the second efficiency increase in HVAC equipment in the last five years, while on the residential side, there will be separate efficiency standards and installation requirements for central air conditioners sold in the northern and southern parts of the U.S.

It is important for contractors to not only be aware of the changes taking place next year, but to take steps now to update inventory plans in order to be prepared for the new efficiency standards.

Changes

The new DOE standards will increase the minimum efficiency of residential equipment approximately 7%, or the equivalent of 1 SEER point and .6 HSPF for most equipment, said Jennifer Butsch, director of regulatory affairs at Emerson. What makes this transition a little more challenging, she said, is that OEM ratings will be based on a new test procedure and result in new metrics — SEER2, HSPF2, and EER2 (see sidebar).

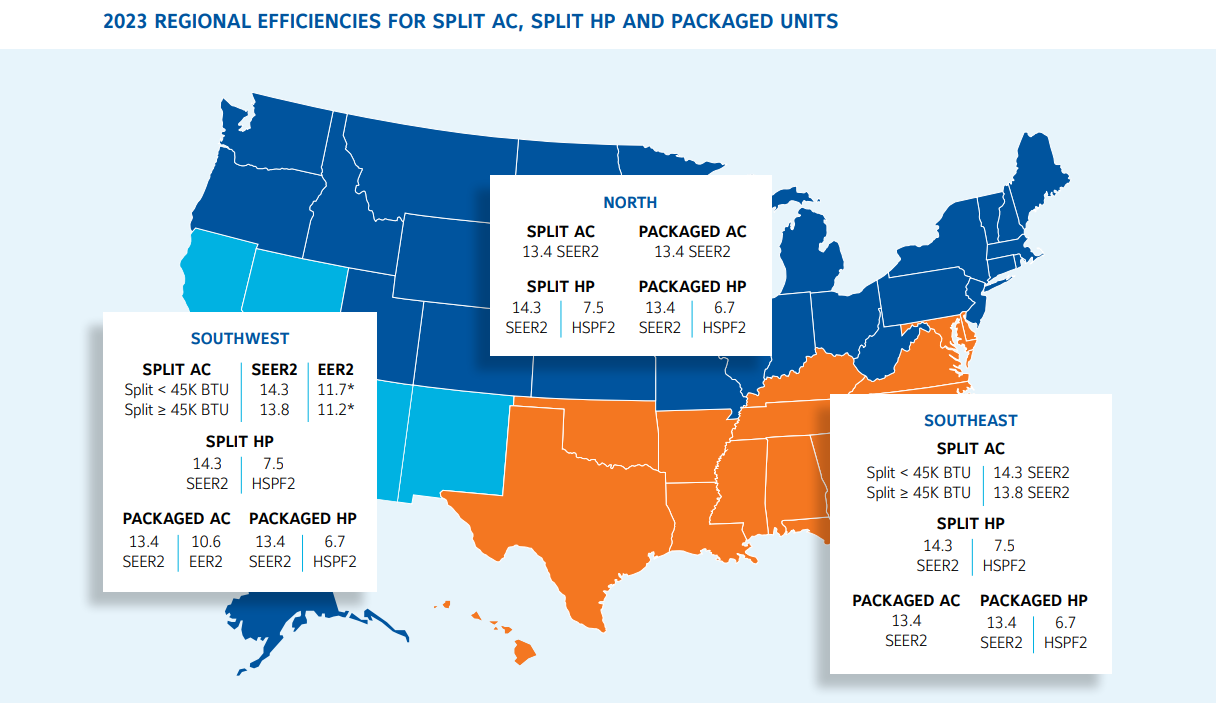

THREE REGIONS: Efficiency standards for single split central air conditioners are still divided into three regions: North, South, and Southwest, with higher SEER2 required for the Southern regions. (Courtesy of Johnson Controls)

“Efficiency standards for single split central air conditioners are still divided into three regions: North, South, and Southwest, with higher SEER2 required for the Southern regions (the same as it is today),” she said. “The new SEER2 minimum will be 13.4 in the North [equivalent to 14 SEER] and 14.3 [15 SEER] in the Southern regions. The new efficiency metrics will be reflected on the updated FTC energy guide labels.”

Another difference is that each of the three regions will have different date-of-installation and date-of-manufacture requirements based on product type, said Chris Forth, vice president of regulatory, codes and environmental affairs, ducted systems at Johnson Controls.

“In the North, sell through of residential air conditioning units built prior to January 1, 2023 is permitted on or after January 1, 2023, but newly manufactured SEER2, EER2 products must meet the 2023 minimum requirements in addition to being tested to a new DOE test procedure,” he said. “Air conditioners in the Southeast and Southwest are date-of-installation products and must be completely installed no later than December 31, 2022; therefore, sell through of air conditioners is not permitted unless their EnergyGuide labels meet the new 2023 SEER/EER minimums.”

The ratings published on a unit’s EnergyGuide label will determine whether or not an air conditioning unit for the Southeast or Southwest region can be installed on or after January 1, 2023, added Forth. The EnergyGuide labels must be at least 15 SEER (for products < 45,000 Btuh or 14.5 SEER for products ≥ 45,000 Btuh) in order to meet the new 2023 SEER minimums. Products in the Southwest must also meet the 2023 EER requirements.

“It’s important to note that the DOE considers heat pumps of all types as a national standard and as thus they are not subject to regional efficiency standards with one exception,” said Forth. “The exception is for single package heat pumps in the Southwest, which requires units also meet a minimum EER.”

On the commercial side, DOE increased the efficiency of air conditioning systems in two phases. The first phase occurred in 2018 and consisted of a 13% increase in minimum efficiency, while the second phase will take place in 2023 and require an additional 15% increase in part-load (IEER) efficiency.

The commercial HVAC market does not have regional standards, and DOE compliance is based on the ship date, said Henry Ernst, regulations and industry organizations manager at Daikin Applied.

Read full article here: https://www.achrnews.com/articles/146585-prepare-now-for-2023-energy-efficiency-standards